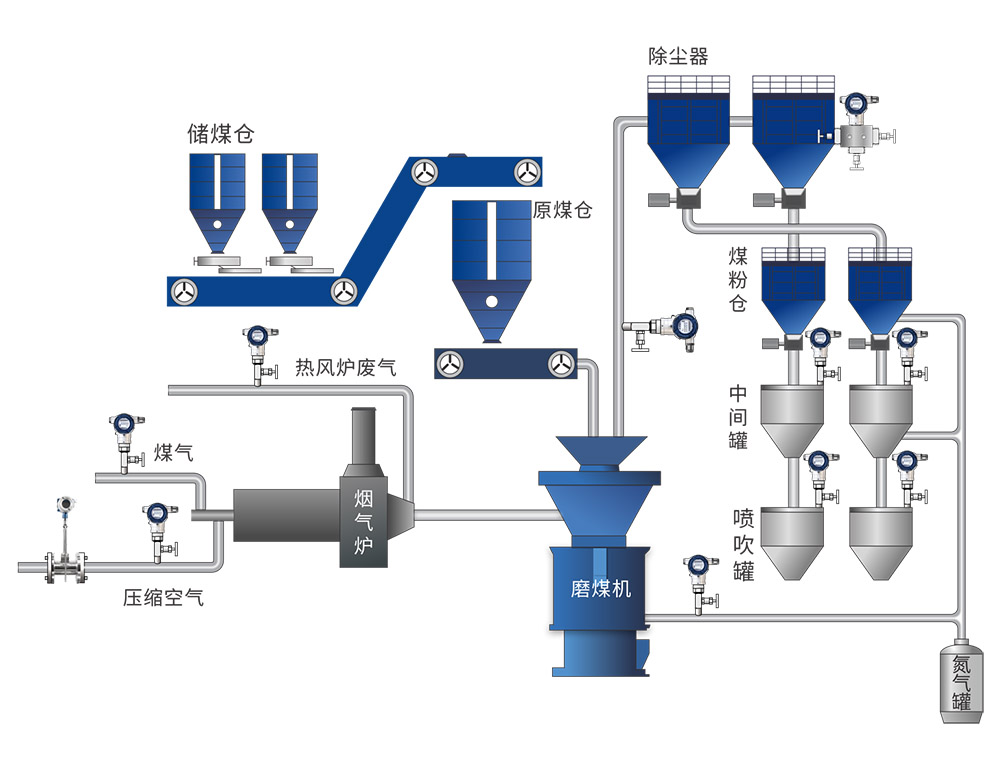

In the metallurgical industry, precise monitoring and control of pressure, liquid level, temperature, and flow rate are key to ensuring the efficiency of the smelting process and product quality. Our comprehensive monitoring solution integrates advanced sensing technology and intelligent control systems, which can work stably in high temperature, high pressure, and harsh environments, provide real-time data and precise control, optimize metallurgical production processes, and ensure safe and efficient operation.

Application Challenge:

1. Extreme environment: Metallurgical production environments typically have high temperatures, pressures, and strong corrosiveness, requiring instruments to have high durability and stability.

2. Real time monitoring: Metallurgical processes require continuous and real-time monitoring of multiple parameters to ensure stable and efficient operation of each link.

3. Data integration and analysis: It is necessary to integrate and quickly analyze various monitoring data to optimize production processes and improve product quality.

4. Maintenance and reliability: Instruments must have high reliability and low maintenance requirements to reduce downtime and maintenance costs.

Solution advantages:

1. High temperature and high pressure resistant design: Our instruments are designed with materials that are resistant to high temperature, high pressure, and corrosion, allowing for long-term stable operation in extreme environments in the metallurgical industry.

2. High precision sensors: equipped with high-precision sensors to ensure accurate measurement of pressure, liquid level, temperature, and flow rate, providing reliable data support for the production process.

3. Support intelligent control system: an integrated intelligent control system that can collect and analyze data in real time, optimize the production process, improve efficiency and product quality.

4. High reliability: By using high-quality components and advanced manufacturing processes, the instrument ensures high reliability and low maintenance requirements, reducing downtime.

5. Security guarantee: The system has multiple security protection mechanisms, including fault self diagnosis and alarm functions, to ensure the safety of the production process.

Contact: Ms. Zeng

Phone: 18186209071

Whatsapp: +86 18186209071

Email: 1347626977@qq.com

Add: 503-4, No.03, Floor 5, Building 2, International Enterprise Center, No.1 Guanshaner Road, Wuhan East Lake New Technology Development Zone

We chat