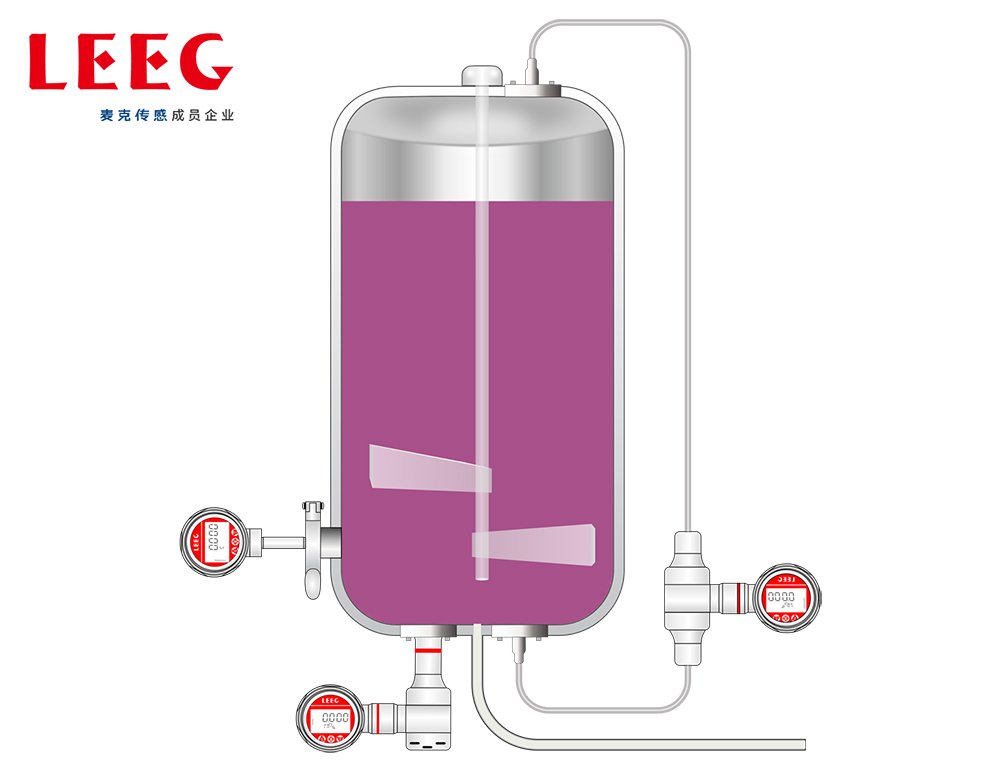

In beverage storage tanks, liquid level transmitters measure the liquid level height of milk or beverages in the tank, helping operators monitor material inventory in real time; The temperature transmitter measures the temperature of the material inside the storage tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration caused by high temperature or affecting the taste of the product due to low temperature.

Application Challenge:

1. Milk and juice contain organic acids, sugars, and other chemical components that can corrode the transmitter. At the same time, sediment or accumulated residue may form in the storage tank, contaminating the sensor surface and affecting measurement accuracy.

2. The transmitters in milk and juice storage tanks must comply with strict hygiene standards to prevent any microorganisms or foreign objects from contaminating the food. At the same time, the sensors need to be regularly cleaned and disinfected to ensure compliance with hygiene requirements.

3. The viscosity and density of juice and milk vary with temperature and composition, which affects the measurement accuracy of the transmitter, especially in liquid level and flow measurement.

4. The structure of the storage tank is complex, and sometimes the installation position of the transmitter is not conducive to accurate measurement (such as dead corners, strong mixing positions, etc.), which may lead to unstable measurement data.

Solution advantages:

1. The sanitary pressure transmitter is made of food grade stainless steel 316L corrosion-resistant material, effectively preventing corrosion.

2. Choose transmitters that comply with EHEDG (European Sanitary Design Equipment Standard) or 3A sanitary standards to ensure no dead corners and easy cleaning.

3. Single crystal silicon technology differential pressure liquid level transmitter can accurately measure changes in low density and low viscosity, and regularly adjust measurement parameters to ensure adaptability to changes in viscosity and density.

4. Optimize installation location and use intelligent algorithms to compensate for measurement errors caused by location, improving data reliability.

Contact: Ms. Zeng

Phone: 18186209071

Whatsapp: +86 18186209071

Email: 1347626977@qq.com

Add: 503-4, No.03, Floor 5, Building 2, International Enterprise Center, No.1 Guanshaner Road, Wuhan East Lake New Technology Development Zone

We chat